- Relief printing

- Intaglio and planographic printing

- Color printing

- Bits and pieces

- Early photography in silver

- Non-silver processes

- Modern photography

- Color notes

- Color photography

- Photography in ink: relief and intaglio printing

- Photography in ink: planographic printing

- Digital processes

- Where do we go from here?

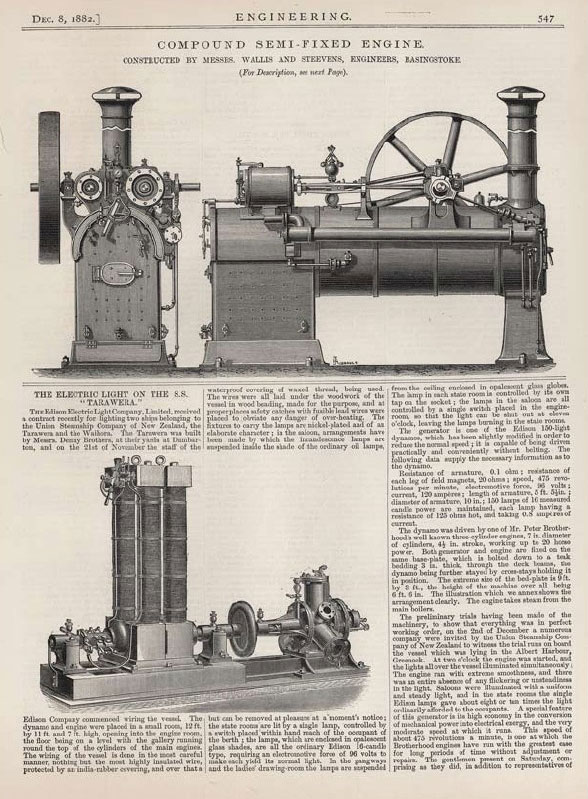

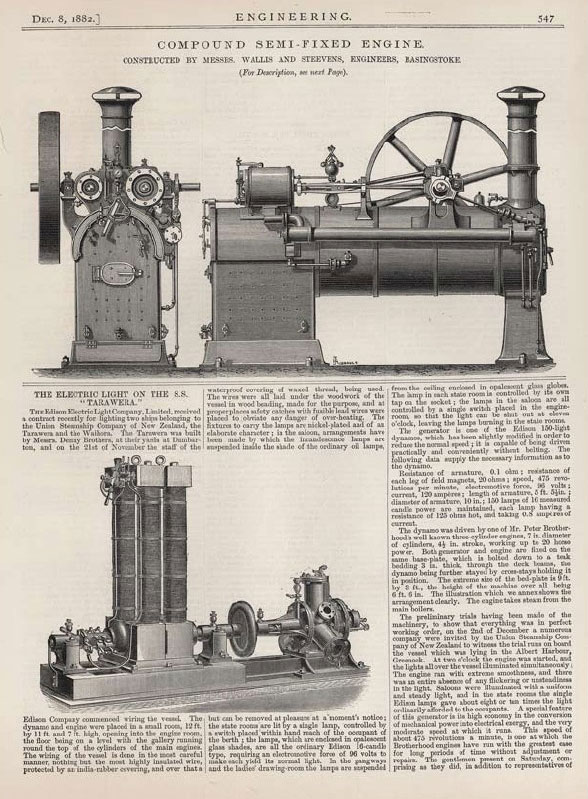

How do you get from wood block to metal?

Letterpress from wood engraving and metal type. J. H. Rimbault. Compound Semi-fixed Engine. 1882. 12 x 8¾ in. (30.5 x 22.2 cm). From the journal Engineering, December 8, 1882.

The blocks for wood engraving had to be very hard; the favored material was boxwood, which is a small tree, so the printing blocks often had to be glued up out of small pieces. But boxwood is dense enough to lock up decently with type in a printing chase. Still more important, the height of the block is extremely stable, since wood undergoes little dimensional change along the direction of its grain when temperature or humidity varies. The wood could be carefully dried, accurately finished to type height, and cut to the size needed for illustrations. The early, semirotary steam-driven presses could dependably print forms properly locked up with metal type and end-grain picture blocks. When presses became fully rotary, around the time that this print was made, the printing was often done from a “stereotype,” a precise casting made from the type and picture blocks.

Letterpress from wood engraving and metal type. J. H. Rimbault. Compound Semi-fixed Engine. 1882. 12 x 8¾ in. (30.5 x 22.2 cm). From the journal Engineering, December 8, 1882.

Stereos were thin and could fit the curved shape of the printing cylinder. Far higher printing speeds were possible on these new presses, in which flat reciprocating surfaces were eliminated.