- Relief printing

- Intaglio and planographic printing

- Color printing

- Bits and pieces

- Early photography in silver

- Non-silver processes

- Modern photography

- Color notes

- Color photography

- Photography in ink: relief and intaglio printing

- Photography in ink: planographic printing

- Digital processes

- Where do we go from here?

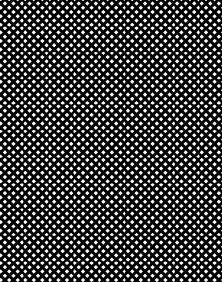

The Letterpress Halftone

A representation of a section of a glass halftone screen, similar to the one used in 1947 to make the reproductions for the book Henri Cartier-Bresson (New York: The Museum of Modern Art). The screen used for that book had approximately 100 clear dots per linear inch, or 10,000 per square inch.

The plain one-impression halftone, printed by letterpress, completely dominated mass-produced photographic publications from about 1900 until the refinement of photo offset lithography in the 1960s. The halftone was cheap, easy to make and print, lent itself to the production of stereotypes (which allowed both type and pictures to be printed on rotary presses), and gave a passable level of quality for most uses. A surprising thing about this technique is that it changed so little between its invention and its demise. The halftone negative was made by photographing the original through a glass screen ruled with a network of tiny apertures. These apertures produced diffuse dots of light that struck the sensitive film or plate.

Halftone print. Henri Cartier-Bresson. Sunday on the Banks of the Marne, France. 1936–38 (printed 1947). 4 x 5 7/8" (10.2 x 14.9 cm). Letterpress printed halftone from Henri Cartier-Bresson (New York: The Museum of Modern Art). © Henri Cartier-Bresson/Magnum, courtesy Fondation Henri Cartier-Bresson

When developed with a high-contrast developer, the dots appeared solid in the negative, but varied in size according to the intensity with which each had been illuminated by the original. The halftone negative thus produced was exposed by contact to a light-sensitive resist coated on a sheet of copper. The resist—usually a fish or animal glue sensitized with bichromate—hardened where exposed to light; the unexposed resist between the dots remained soft, and was washed away, uncovering the copper. Next came an etch (usually ferric chloride), which dissolved these areas of bare copper, the spaces between the dots. As it cut below the surface of the copper it also cut into the sides of the dots, which diminished in size, making the print lighter and lighter as the etching went on.

Enlargement of Halftone print. Henri Cartier-Bresson. Sunday on the Banks of the Marne, France. 1936–38 (printed 1947) 4 x 5 7/8” " (10.2 x 14.9 cm). Letterpress printed halftone from Henri Cartier-Bresson (New York: The Museum of Modern Art). © Henri Cartier-Bresson/Magnum, courtesy Fondation Henri Cartier-Bresson. An eight-times enlargement showing the halftone dot pattern. Imperfect inking and squeezed transfer of ink to paper have produced considerable distortion of the halftone dot.

This undercutting could be arrested, through an etching trick with a compound called “dragon’s blood” (believe it or not), but the undercutting supplied a practical limit to the ruling of the screen—about 150 dots per linear inch. Smaller highlight dots from a finer screen would be eaten away and not print. No matter how well a letterpress halftone is printed, the image will have a somewhat rough appearance and the resolution will be low when compared to an actual photographic print. The second major difficulty with the letterpress halftone was that it only printed well on a hard, smooth, clay-coated sheet.

The copper plate had to be lightly inked (to avoid filling in the spaces between the dots), then evenly pressed against the paper. Halftones were printed on presses that held the paper on a cylinder, so that the full pressure of the press was applied to the narrow section of the plate that the cylinder contacted. Both paper and copper are hard, so if either one was at all uneven, or if the pressure was not quite right, the transfer would be flawed and the print would suffer. The vast majority of printed letterpress halftones had visible difficulties because of imperfect ink transfer. This problem was never solved, and offset printing, which uses a soft intermediate blanket between plate and paper to sidestep the whole issue, would completely kill letterpress within a couple of decades of its perfection in the years following World War II.